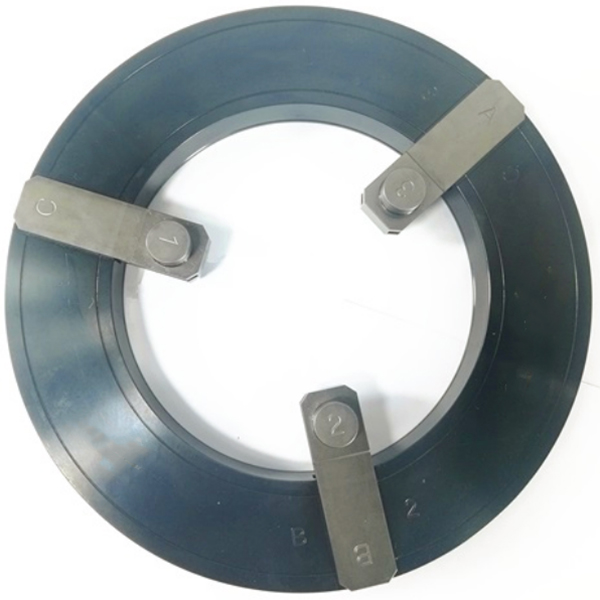

Schunk says its Rota THW3 quick-change jaw chuck is particularly beneficial for users who produce small and medium quantities and are frequently switching between jobs.

Schunk’s Rota THW3 quick-change jaw chuck is designed for short set-up times and low maintenance. According to the company, the Schunk Rota THW3 quick-change jaw chuck is particularly beneficial for users who produce small and medium quantities and are frequently switching between jobs. Magnetic Chuck Lathe

The lathe chuck with the patented sealing system reportedly accelerates the jaw change on CNC lathes, pick-up lathes and turning-milling centers, while at the same time providing jaw change repeatability up to <0.02 mm. This means that jaw sets that have been turned out once can be used repeatedly, even with demanding tolerances.

The jaw stroke of the straight toothed base jaws is 6.7 mm to 10.5 mm, depending on the size. A ring piston with a direct power transmission is said to ensure a high degree of efficiency, and in the smallest size, 200, the chuck already achieves a clamping force of 64 kN; from size 400 it is 240 kN. Its hardened and stiff base body ensures that precise and reliable machining can be carried out even under maximum stress. The jaw features a large chuck bore from 52 mm (size 200) to 165 mm (size 630), protective rifles that can be exchanged from the front and the possibility of internal and external tension. There is also the option of supplementing the chuck with an adjustable stop.

Read: Automation and Flexibility Counter Inflation at BI-MU 2022

The Rota THW3 chuck has also been enhanced with large tool storage, multi spindles and modular machine controls. The company says these enhancements enable faster throughput, flexibility and accuracy.

Matching chuck jaws for the Schunk Rota THW3 chuck can be found using Schunk’s chuck jaw quickfinder. The user can choose from a list of all matching chuck jaws from over 1,200 jaw types.

The force that holds the toolholder in the machining center's spindle can weaken over time. If you haven't checked drawbar force in a while, this may be the weak link in your process.

A tooling system consisting of interchangeable cutting units and standardized locking units has a lot to offer users of CNC machines, whether for turning, milling, or both on a turn mill. These guidelines will help you think clearly about how modular, quick-change tooling can benefit your shop.

Standard Cnc Lathe Chuck Machining Cutting Tool The book on hydraulic toolholders is that they are fussy to set, fragile to operate and expensive to buy. So why do many shops choose them over other holders that seem less demanding? This Chicago mold builder has good reasons for its choice.